Inconel 625 Mesh: The Ultimate Solution for Extreme Environments

Inconel 625 Mesh: The Ultimate Solution for Extreme Environments

Blog Article

Introduction

In the world of high-performance materials, Inconel 625 mesh stands out as a leading solution for applications exposed to extreme temperatures, corrosive environments, and high-pressure conditions. Whether you're in aerospace, marine, chemical processing, or power generation, this advanced mesh alloy offers unmatched durability and versatility.

In this guest post, we'll explore what makes Inconel 625 mesh so valuable, its key properties, applications, and how it compares to other metal meshes on the market.

What is Inconel 625 Mesh?

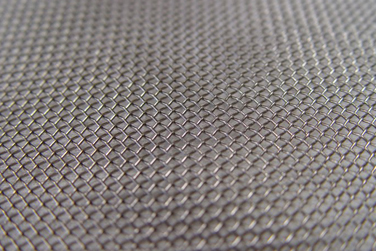

Inconel 625 is a nickel-based superalloy known for its exceptional strength, oxidation resistance, and corrosion resistance. When formed into a mesh structure, it becomes ideal for filtration, separation, reinforcement, and structural applications in demanding environments.

The mesh is typically woven or welded from wire made of Inconel 625 alloy, creating a flexible yet strong material that maintains its integrity under stress.

Key Properties of Inconel 625 Mesh

Here are the standout features that make Inconel 625 mesh unique:

-

Excellent Corrosion Resistance – Resists pitting, crevice corrosion, and stress corrosion cracking in both acidic and seawater environments.

-

High Temperature Stability – Performs reliably in temperatures up to 1000°C (1832°F).

-

Exceptional Strength – Maintains structural integrity under mechanical stress and high-pressure conditions.

-

Oxidation Resistance – Withstands oxidative environments, making it ideal for aerospace and thermal applications.

-

Versatility – Can be used in fine mesh sizes for filtration or heavier gauges for structural support.

Common Applications of Inconel 625 Mesh

Because of its advanced material properties, Inconel 625 mesh is used in a wide range of industries:

-

Aerospace: Thermal insulation blankets, exhaust systems, and engine components.

-

Marine: Offshore platforms, seawater filtration, and piping protection.

-

Chemical Processing: Acidic fluid filtration, reactor linings, and containment barriers.

-

Power Generation: Heat exchangers, nuclear reactor components, and turbine containment.

-

Environmental Engineering: High-efficiency filtration in air and water treatment systems.

While stainless steel mesh may be cost-effective for general use, Inconel 625 mesh is a better investment for high-stakes applications where failure is not an option.

Choosing the Right Mesh Specifications

When selecting Inconel 625 mesh, consider the following:

-

Mesh Count (wires per inch): Determines filtration precision.

-

Wire Diameter: Influences strength and open area.

-

Weave Type: Plain weave, twill weave, or Dutch weave for filtration purposes.

-

Finish & Treatment: Pickled, annealed, or coated depending on your application.

A reputable supplier will help customize mesh parameters to match your exact requirements.

Final Thoughts

Inconel 625 mesh is more than just a material—it's a performance solution engineered for the most challenging environments on earth (and beyond). Its combination of corrosion resistance, strength, and thermal stability makes it a top choice for industries that demand reliability and longevity.

If you're planning a project that requires filtration, structural reinforcement, or heat resistance in aggressive conditions, Inconel 625 mesh should be at the top of your list.

About the Author

wiremeshes specializes in high-performance metal solutions, providing expert guidance and premium alloys for industrial applications. For custom mesh solutions or technical consultations, feel free to get in touch at

contact - 9903647111

Email - wiremeshes1@gmail.com

Website - https://www.wiremeshes.com/

Report this page